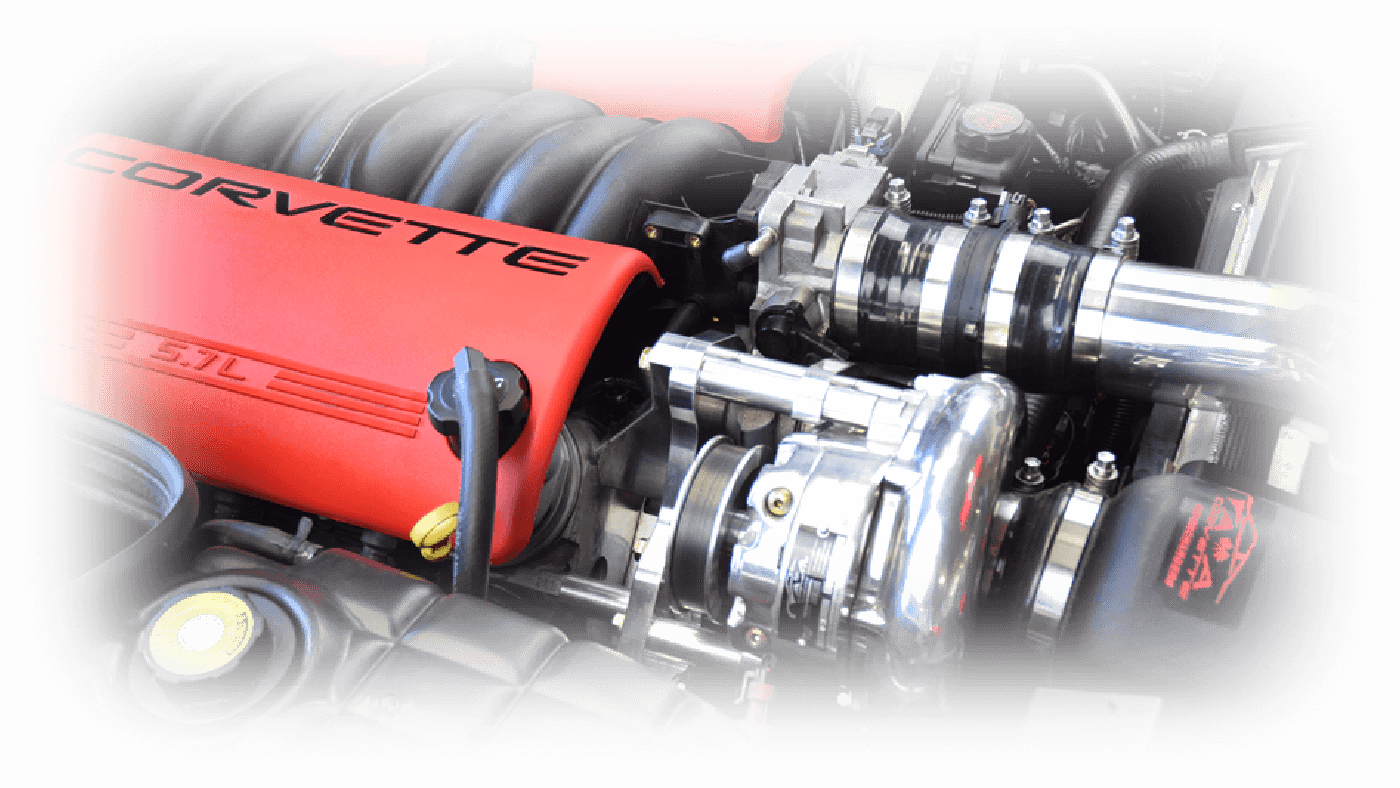

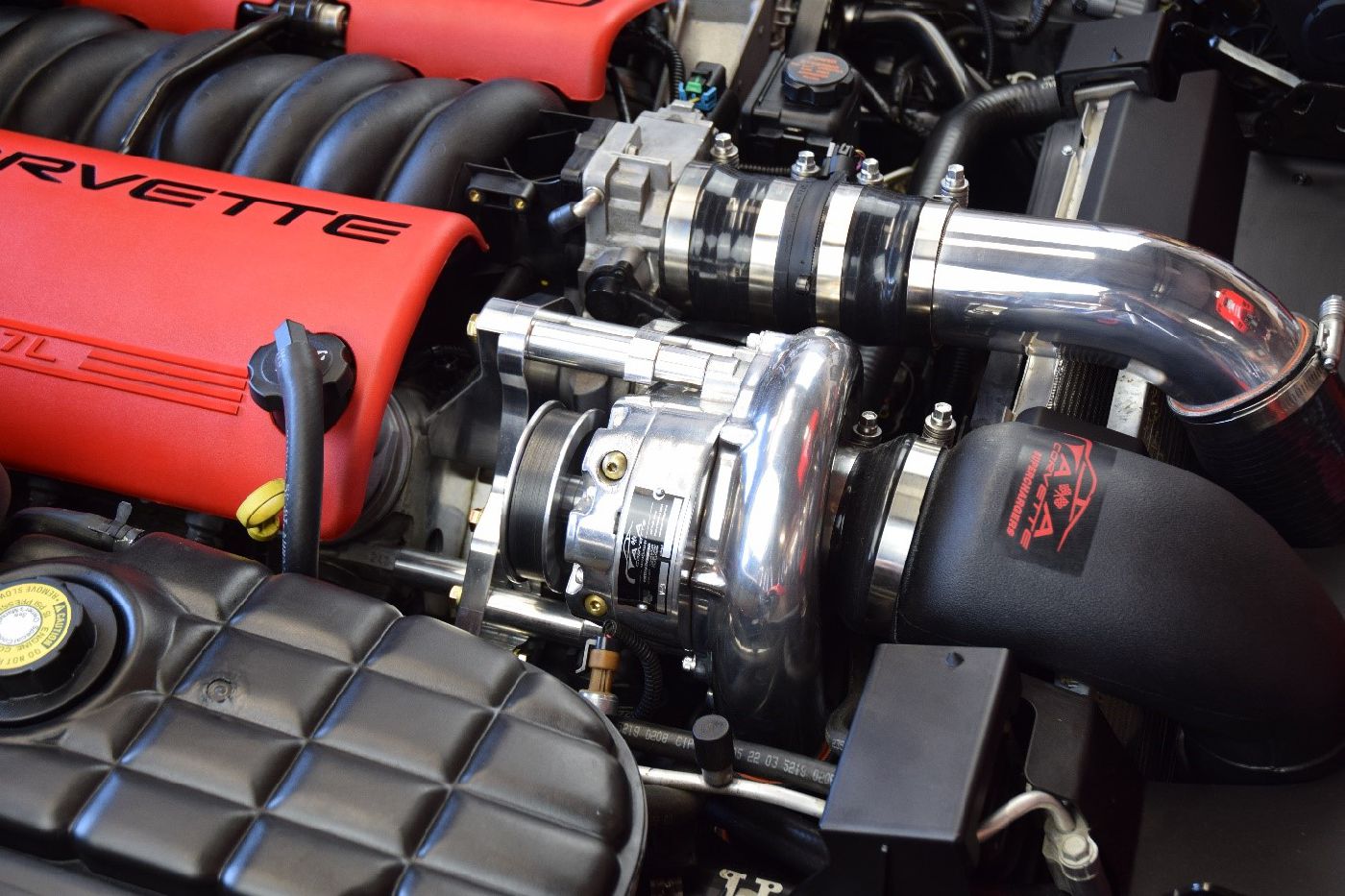

A&A SUPERCHARGER SYSTEM FOR C5 CORVETTE

This is where it all started for A&A back in the 1990s.

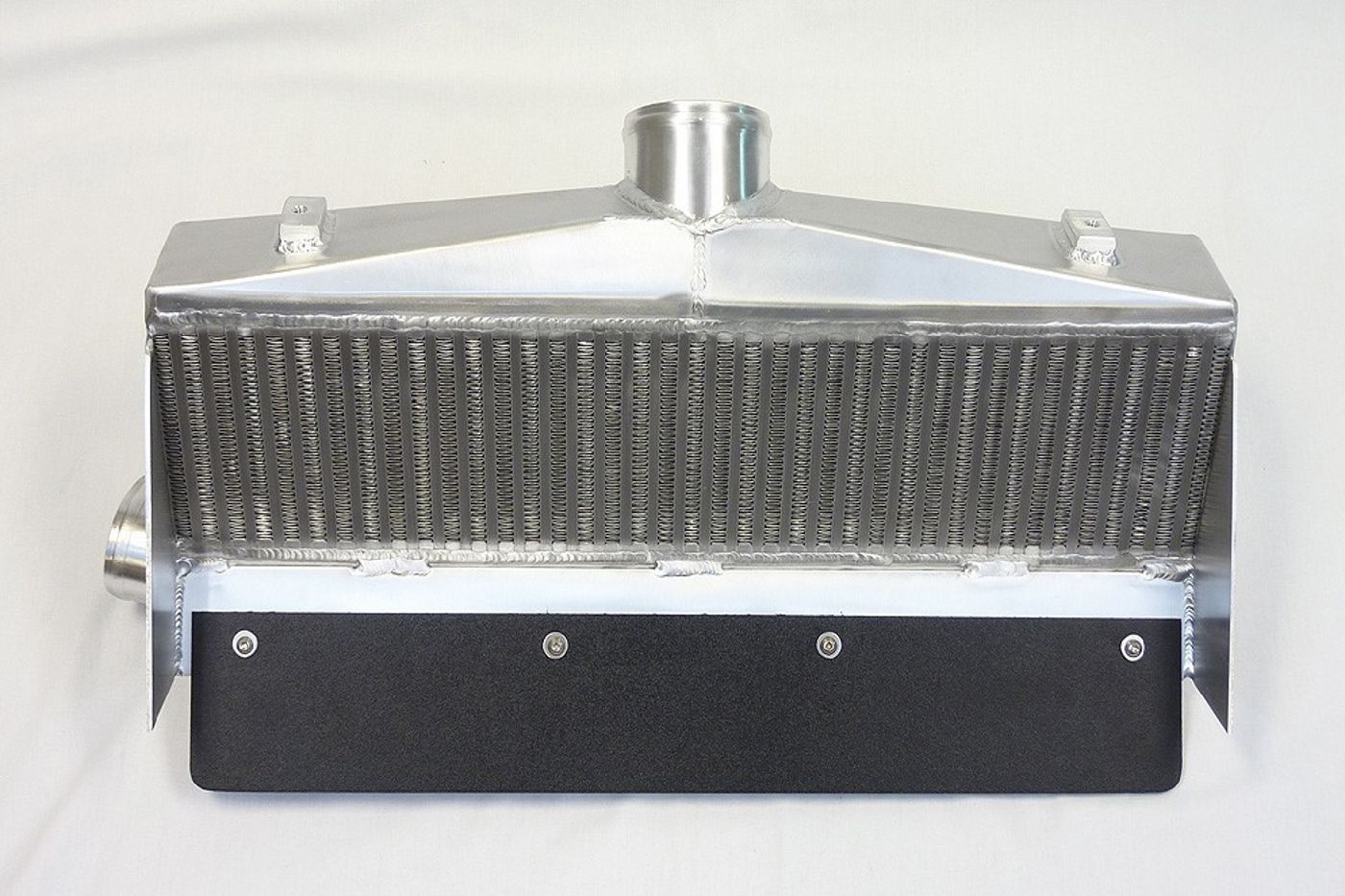

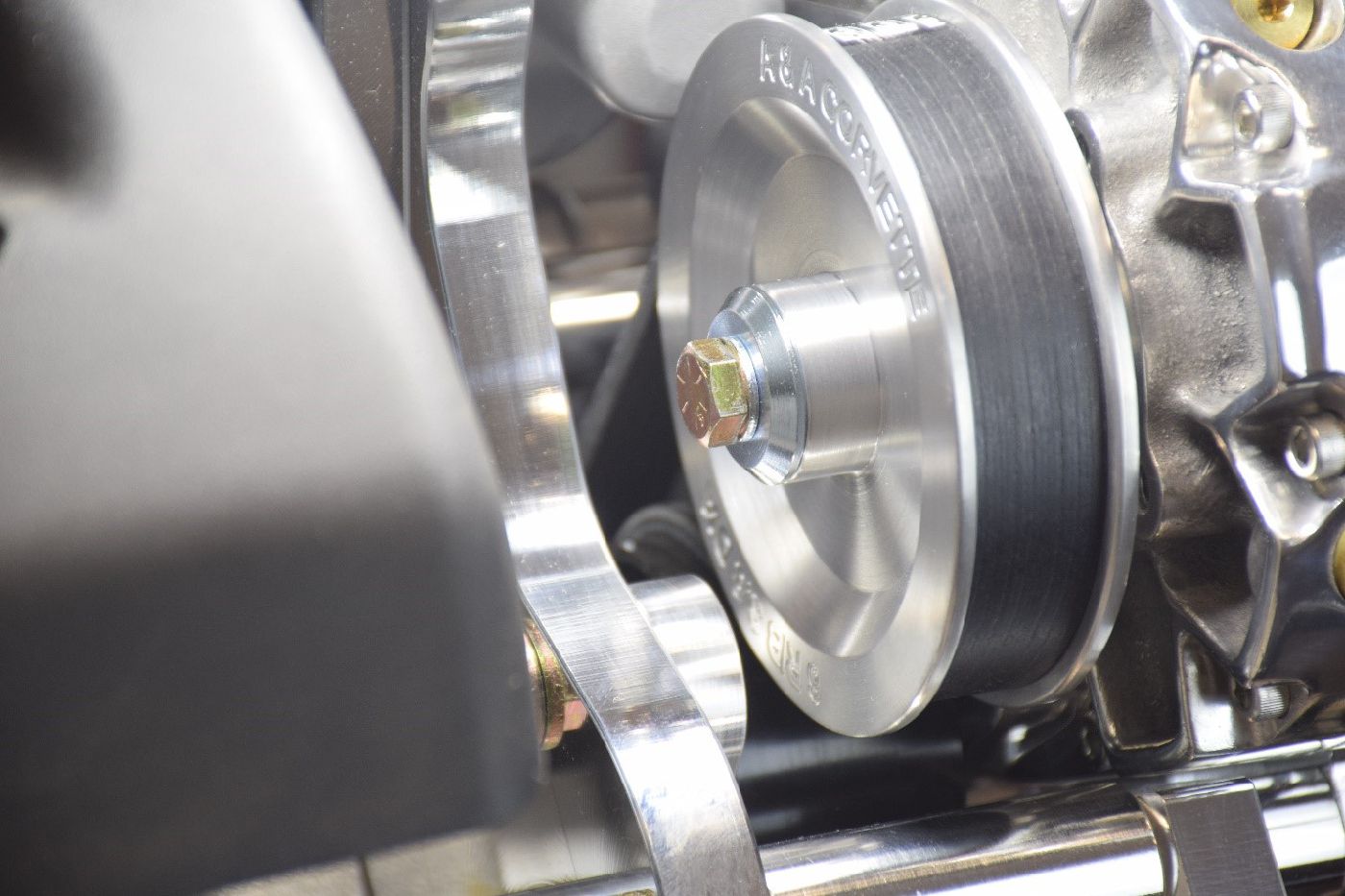

C5 continues to be a great platform for supercharging due to the affordability and number of vehicles available. While some manufacturers have stopped supporting C5, we not only support, but continue to improve existing parts and design new ones. C5 is, and will continue to be, a great hotrod platform for some time.

SHARE THIS PAGE!